FJY-Series Anticorrosive and Neutral Zinc-Nickel Alloy Brush Plating Technology

Abstract

In order to solve the corrosion of the acidic solution, such as the activation solution in the brush plating process, to the formed protective coating, especially the corrosion of the zinc-based alloy coating such as galvanizing, zinc-nickel alloy, zinc-cobalt alloy, etc., the FJY series brush plating has successfully developed a set of technologies to prevent corrosion of large steel components without the need to mask the non-plated surface.

Heading 1

Brief introduction of zinc-nickel alloy anticorrosive coating

So far, zinc-nickel alloy is the most studied and widely used zinc-based alloy coating among zinc-based alloy coatings. Although there were reports on the research of zinc-nickel alloy (Zn-Ni alloy) electroplating process as early as 1905, in the late 1980s, developed countries began to apply zinc-nickel alloy coating on protecting the surface of steel materials on a large scale. Experimental research and practical application results show that the corrosion resistance of zinc-nickel alloy coating is 6-10 times that of pure zinc coating and 3-4 times that of cadmium coating. Proper passivation treatment can also further improve the corrosion resistance of the zinc-nickel alloy coating.

Problems in zinc-nickel alloy brush plating

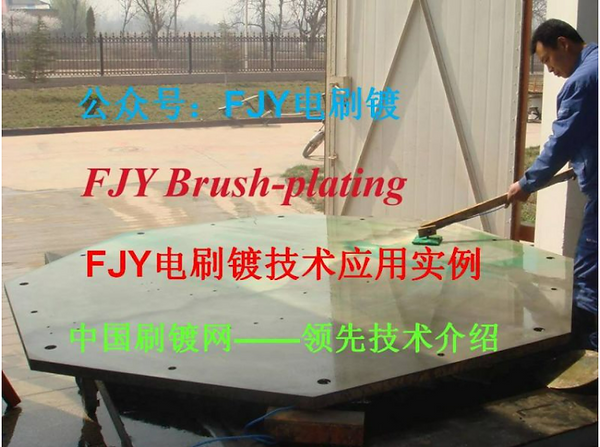

It is commonly known among brush plating engineers that when the size of the workpiece to be plated is large, the workpiece needs to be divided into blocks. Either the plated or unplated parts need to be shielded and protected.

When it comes to facilitating the anti-corrosion feature to steel based components, most likely large workpieces are to be dealt with. Obviously, considering the amount of sheltering work, it imposes a challenge to the anti-corrosion construction of large-scale projects.

Brief introduction of FJY-series neutral zinc-nickel alloy brush plating technologies for steel corrosion protection

1. Degreasing (removing rust)

The first step of the brush plating process is to clean the surface to be plated on the steel structure. Mechanical derusting and chemical (electrochemical degreasing) are necessary steps.

2. Activate the plated surface using neutral and anticorrosive zinc-nickel brush plating activation solution

Dip a plating pen into the neutral activating solution and activate the surface to be plated. Since the activation solution is non-corrosive to the steel and zinc-based alloy coatings, there is no need to shield the surface of the workpiece.

3. Plate anticorrosive coating using FJY-series neutral and anticorrosive zinc-nickel alloy solution

Dip a plating pen into the neutral zinc-nickel alloy plating solution, and perform brush plating according to the parameters of the plating solution until the anti-corrosion construction of the entire steel component is completed.